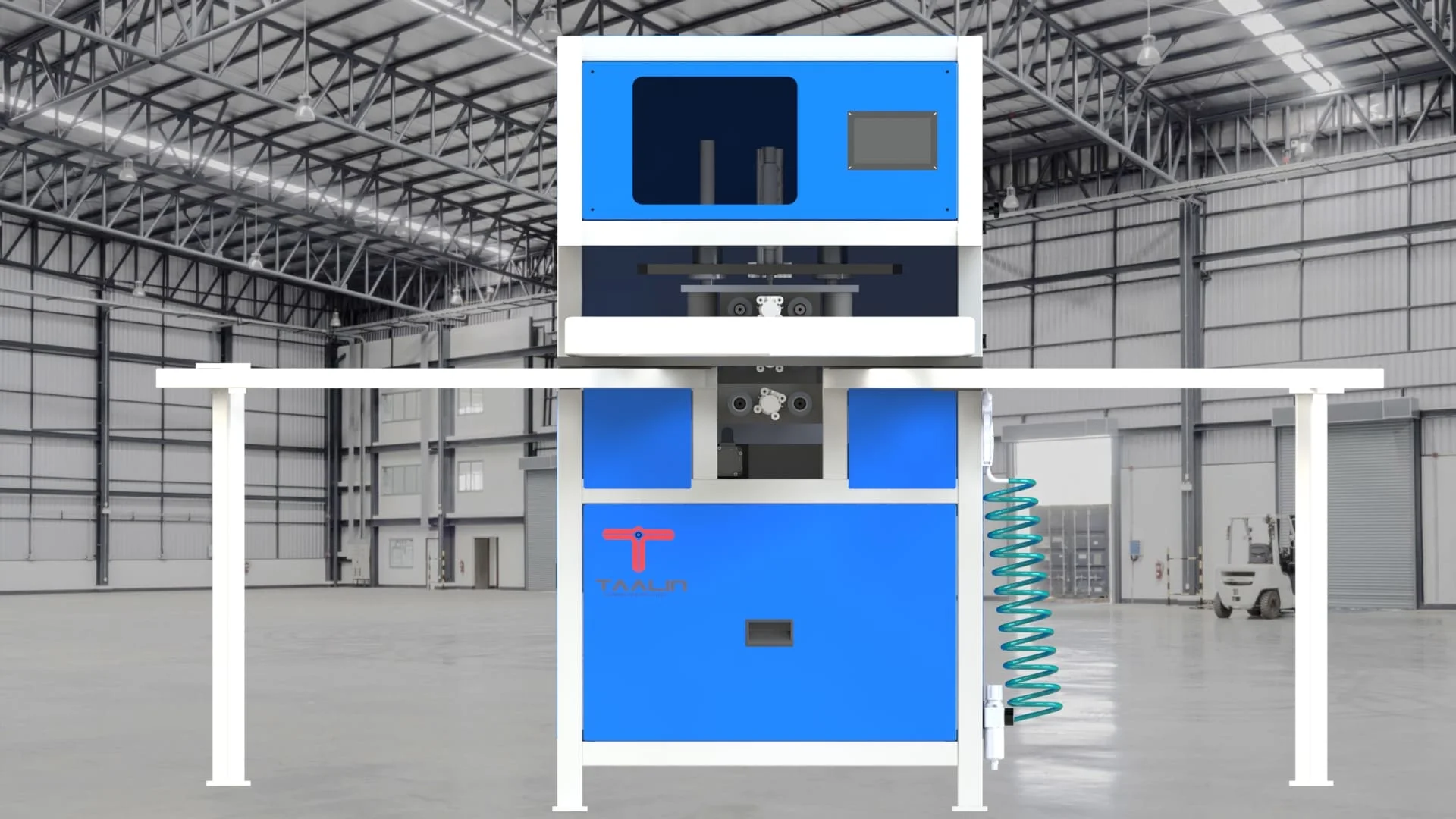

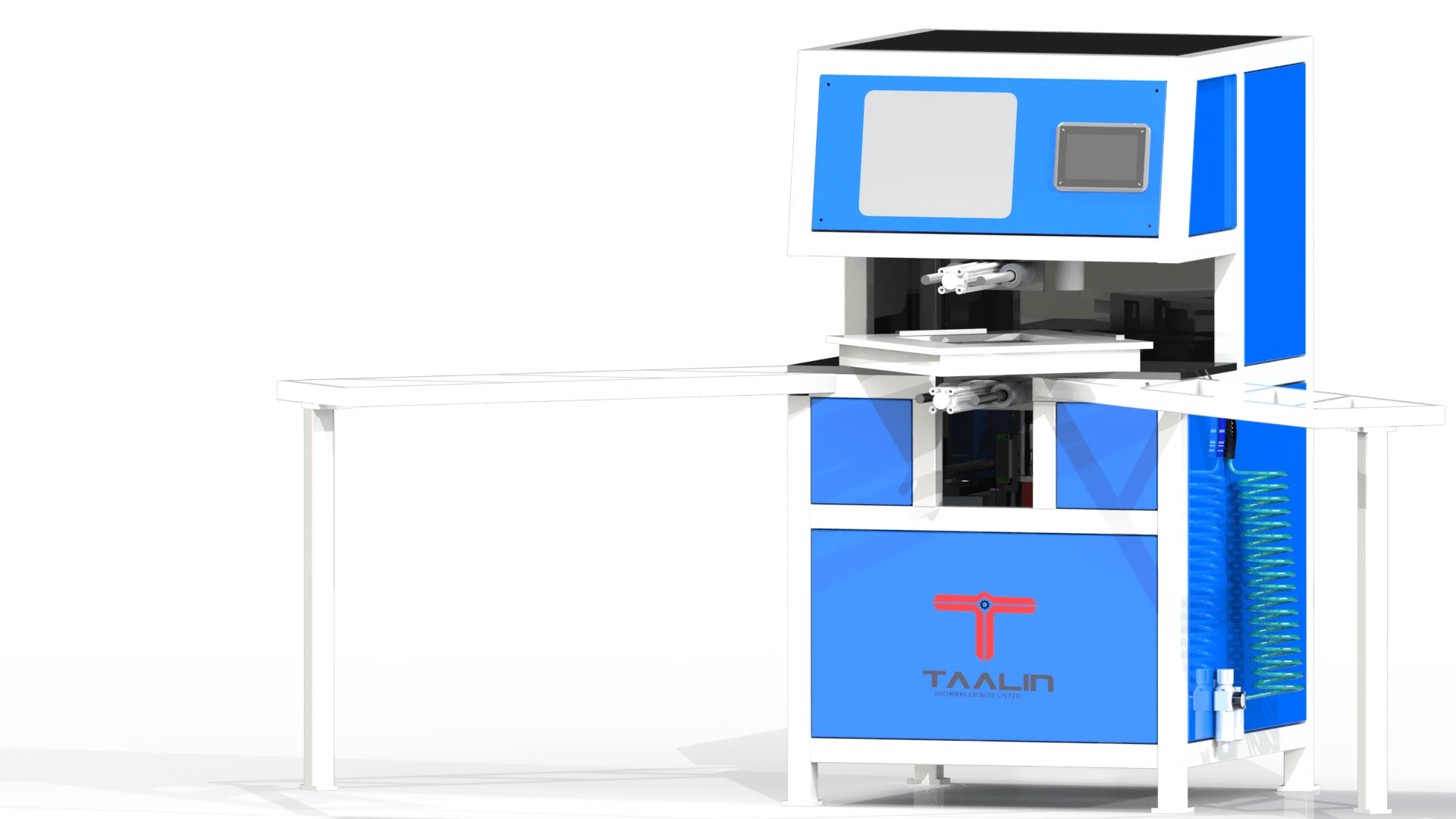

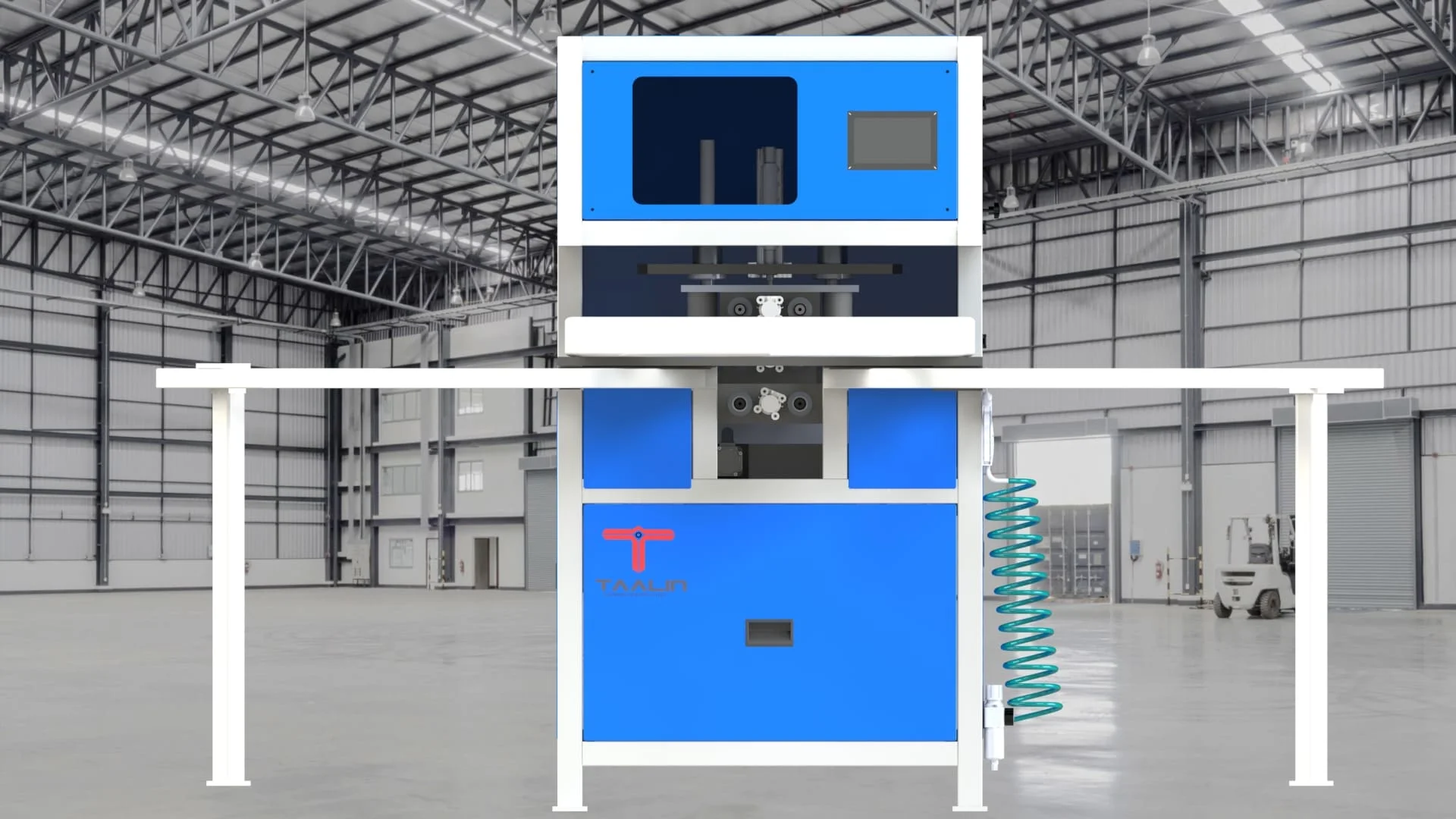

UPVC CNC Corner Cleaning Machine in India

Taalin Machinery & Robotics Pvt. Ltd. is a prominent UPVC CNC Corner Cleaning Machine Manufacturer in India. Our precision-engineered machines are trusted by professionals for their durability, efficiency, and consistent performance. Designed to streamline UPVC profile cleaning, our machines ensure flawless corner finishing, reducing manual labor and maximizing productivity. With cutting-edge technology and robust construction, Taalin's UPVC CNC Corner Cleaning Machines meet the high demands of the modern manufacturing industry.

Whether you're in large-scale production or custom fabrication, our solutions are built to deliver accuracy and reliability. Trusted across India, we are committed to helping businesses achieve seamless operations with advanced machinery. Partner with Taalin Machinery for industry-leading machinery that drives results and meets your manufacturing needs.

- Precision Cleaning with CNC Technology: Our machine utilizes advanced CNC (Computer Numerical Control) technology, ensuring precise corner cleaning. It eliminates manual errors, delivering uniform results with every operation, making it ideal for high-quality UPVC frame production.

- Multifunctional Cleaning Capability: Equipped with specialized tools, our machine can clean various profiles, including external, internal, and grooved corners. This versatility enhances productivity by catering to diverse manufacturing needs in a single setup.

- Automated Operation for Maximum Efficiency: With its fully automated system, our machine minimizes human intervention. Features like automatic feeding, cutting, and cleaning streamline the process, reducing production time and improving overall efficiency.

- High-Speed Performance: Our machine is designed for speed without compromising on accuracy. Its high-performance motor and precise programming ensure swift operation, making it suitable for bulk production environments.

- User-Friendly Interface: Our machine features an intuitive touchscreen interface, allowing operators to set parameters, adjust settings, and monitor progress easily. This ease of use reduces training time and ensures seamless operation.